The White Tower (Tor Alva) is an over 24-meter tall structure comprised of 102 3D printed individual columns constructed using a concrete extrusion process developed at the DBT group of the Swiss Federal Institute of Technology (ETH Zurich). It is dubbed as “one of the world’s tallest entirely 3D-printed structures.”

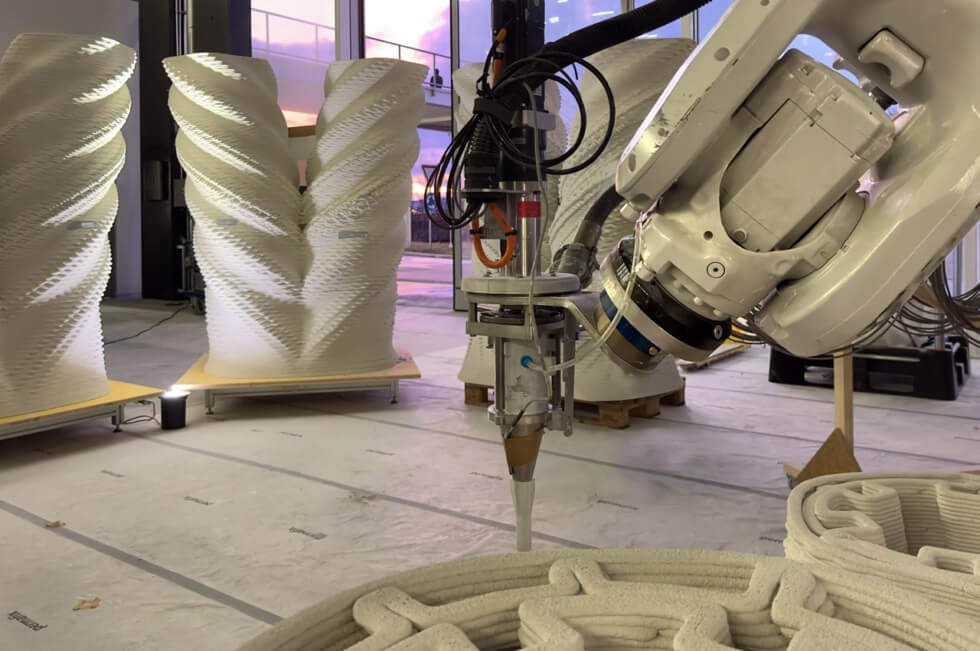

This novel fabrication process involves a of robot applying 5mm thin layers of soft white concrete through a nozzle. The material is soft enough to bond together and form homogenous components. It also hardens fast enough to support the successive layers. The concrete extrusion does not need any formwork and enables concrete to be applied very specifically only where needed.

This way, minimizing its consumption by half and avoiding waste. This process also renders a modular structure that can be setup or installed on site. The White Tower can be disassembled so that it can be rebuilt in another location. A mobile factory will also be setup on site to reduce the need to transport the large elements.

Its entire structure is designed using custom software to precisely define the geometry and send the needed data directly to the printing robots. Thus, enabling the efficient manufacturing of non-standard and tailor-made elements that otherwise cannot be formed using conventional technologies.

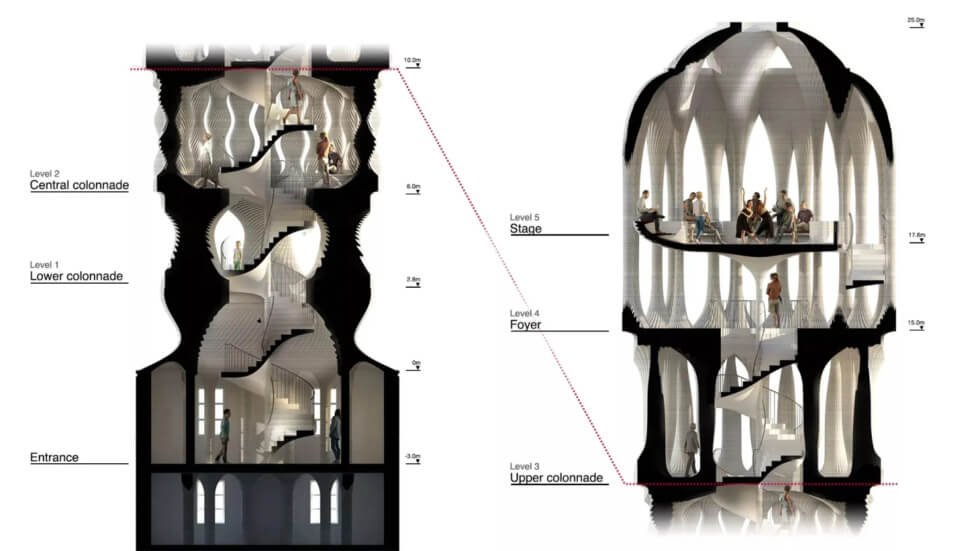

The lower rooms of the White Tower feature heavy, squat columns that create narrow, imposing spaces. A spiral staircase leads to the rooms on the upper floors where it becomes noticeably lighter and airier. The highest floor has a vaulted hall that can be used for art installations and for music and theater performances and can sit 45 people.

At a distance, the White Tower appears filigree and light in its Baroque-inspired style. Its bright materials and bold structures evoke architectural play of light and shadow. Meanwhile, its idiosyncratic openings bring out a welcoming glow at night along old Julier Pass road.

Learn More Here

Images courtesy of ETH Zurich